Tubes smashed to ribbons in big nano advance

Nano-engineers keep finding new uses for ‘nanoribbons’, and a recent research project makes the tiny strips much easier to create.

Nano-engineers keep finding new uses for ‘nanoribbons’, and a recent research project makes the tiny strips much easier to create.

Carbon nanotubes “unzipped” into graphene nanoribbons by a chemical process have found a range of experimental uses in all kinds of projects, but the method to unzip them has been cost and energy-intensive.

Now, a team from Rice University has found a remarkably simple way to get nanotubes to form into nanoribbons – smashing them into a hard surface at close to 7,000 metres per second.

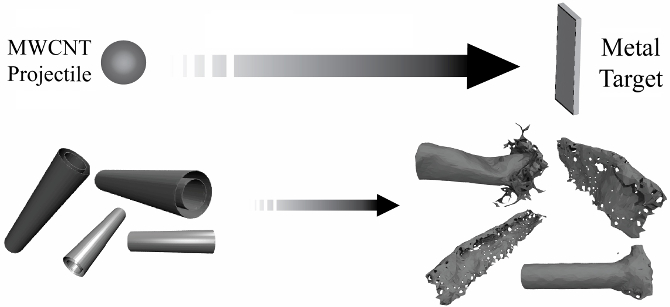

The US tam discovered that nanotubes which hit their target end-first turn into mostly ragged clumps of atoms. However, nanotubes that broadside their target unzip into handy ribbons.

The ribbons can be used in composite materials for strength and applications that take advantage of their incredible electrical properties.

To make the discovery, researchers fired pellets of randomly oriented, multi-walled carbon nanotubes from a gas gun built with funding from NASA.

The gun was designed to test satellite equipment against impacts from microscopic meteorites.

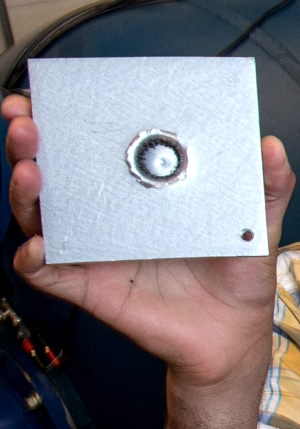

Back on Earth, carbon pellets hit an aluminium target in a vacuum chamber at about 24,100 km/h.

When the team inspected the resulting carbon rubble, they found nanotubes that smashed into the target end first or at a sharp angle simply deformed into a crumpled nanotube, but tubes that hit lengthwise split into ribbons with ragged edges.

“Hypervelocity impact tests are mostly used to simulate the impact of different projectiles on shields, spacecraft and satellites,” Rice Uni grad student Sehmus Ozden said.

“We were investigating possible applications for carbon nanotubes in space when we got this result.”

“Until now, we knew we could use mechanical forces to shorten and cut carbon nanotubes. This is the first time we have showed carbon nanotubes can be unzipped using mechanical forces.”

Simulations of the impact showed that when multi-walled tubes hit the target, the outer tube flattens, hitting the inside tubes and unzipping them in turn.

Single-wall nanotubes do just the opposite; when the tube flattens, the bottom wall hits the inside of the top wall, which unzips from the middle out to the edges.

It appears that the even distribution of stress along the belly-flopping nanotube, which is many times longer than it is wide, breaks carbon bonds in a line nearly simultaneously.

Ozden said the process eliminates the need to clean chemical residues from nanoribbons produced through current techniques.

“One-step, chemical-free, clean and high-quality graphene nanoribbons can be produced using our method. They’re potential candidates for next-generation electronic materials,” he said.

More details have been published in the journal Nano Letters.

Print

Print