Platinum mix could save emissions

Australian researchers have created a platinum catalyst at room temperature - pioneering a new technique that could drastically reduce emissions for industrial processes.

Australian researchers have created a platinum catalyst at room temperature - pioneering a new technique that could drastically reduce emissions for industrial processes.

Platinum is very effective as a catalyst (the trigger for chemical reactions) but is not widely used at industrial scale because it is expensive.

Most catalysis systems involving platinum also have high ongoing energy costs to operate.

Normally, the melting point for platinum is 1,700°C. When used in a solid state for industrial purposes, there needs to be around 10 per cent platinum in a carbon-based catalytic system.

But scientists at UNSW Sydney and RMIT University have found a way to use tiny amounts of platinum to create powerful reactions, and without expensive energy costs.

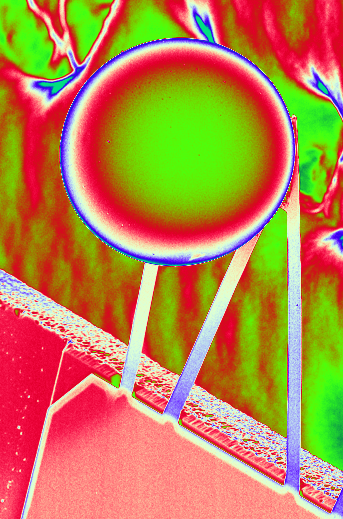

The team combined platinum with liquid gallium, which has a melting point of just 29.8°C - room temperature on a hot day.

When combined with gallium, the platinum becomes soluble, meaning it melts without having to fire up a hugely powerful industrial furnace.

Being able to use trace amounts of liquid platinum to create cheap and highly efficient chemical reactions at low temperatures could open a pathway to dramatic emissions reductions in crucial industries.

When combined with liquid gallium, the amounts of platinum required are small enough to significantly extend the earth’s reserves of this valuable metal, while potentially offering more sustainable solutions for CO2 reduction, ammonia synthesis in fertiliser production, and green fuel cell creation, together with many other possible applications in chemical industries.

The researchers say processing at an elevated temperature will now only be required at the initial stage, when platinum is dissolved in gallium to create the catalysis system. Even then, it requires temperatures of around 300°C for an hour or two, nowhere near the continuous high temperatures often required in industrial-scale chemical engineering.

To create an effective catalyst, the researchers needed to use a ratio of less than 0.0001 platinum to gallium.

Most remarkably of all, the resulting system proved to be over 1,000 times more efficient than its solid-state rival (the one that needed to be around 10 per cent expensive platinum to work).

There are more advantages too. Because it is a liquid-based system, it is also more reliable. Solid-state catalytic systems eventually clog up and stop working, but that is not a problem here. Like a water feature with a built-in fountain, the liquid mechanism constantly refreshes itself, self-regulating its effectiveness over a long period of time and avoiding the catalytic equivalent of pond scum building up on the surface.

The mechanism is also versatile enough to perform both oxidation and reduction reactions, in which oxygen is provided to or taken away from a substance respectively.

Using advanced computational chemistry and modelling, the research team was able to identify that the platinum never becomes solid, right down to the level of individual atoms.

“What we found is the two platinum atoms never came into contact with each other,” says researcher Dr Nastaran Meftahi.

“They were always separated by gallium atoms. There is no solid platinum forming in this system. It’s always atomically dispersed within the gallium. That’s really cool and it’s what we found with the modelling, which is very difficult to observe directly through experiments.”

Dr Andrew Christofferson said the team appears to have come up with some entirely novel results.

“The platinum is actually a little bit below the surface and it’s activating the gallium atoms around it. So the magic is happening on the gallium under the influence of platinum,” he said.

“But without the platinum there, it doesn’t happen. This is completely different from any other catalysis anyone has shown, that I’m aware of. And this is something that can only have been shown through the modelling.”

These findings, which focus on platinum, are just a drop in the liquid metal ocean when it comes to the potential of these catalysis systems. By expanding on this method, there could be more than 1,000 possible combinations of elements for over 1,000 different reactions.

More details are accessible here.

Print

Print