Open efforts slash 3D costs

Bioengineering researchers have modified a commercial-grade laser cutter to create a low-cost laser sintering platform that can print intricate 3-D objects from powdered plastics and biomaterials.

Bioengineering researchers have modified a commercial-grade laser cutter to create a low-cost laser sintering platform that can print intricate 3-D objects from powdered plastics and biomaterials.

A team from Rice University in the US has launched OpenSLS – a system that could greatly reduce costs and allow researchers to work with their own specialised powders and materials.

The OpenSLS platform is designed as an open-source device similar to commercially available selective laser sintering (SLS) platforms, but the system costs at least 40 times less than its commercial counterparts.

The first OpenSLS system was built using low-cost, open-source microcontrollers at a cost of less than $10,000, whereas commercial SLS platforms start at around $400,000 and can easily reach $1 million.

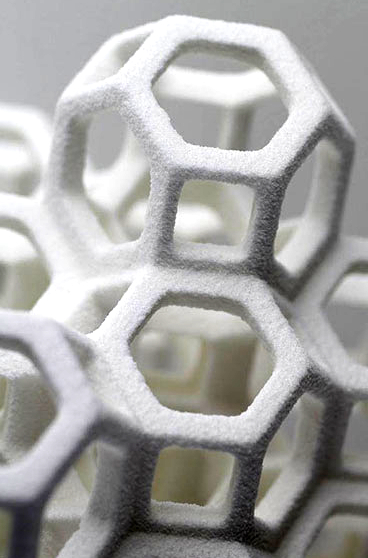

“SLS technology has been around for more than 20 years, and it's one of the only technologies for 3-D printing that has the ability to form objects with dramatic overhangs and bifurcations,” said engineer Jordan Miller, assistant professor of bioengineering at Rice, specialising in 3-D printing for tissue engineering.

“SLS technology is perfect for creating some of the complex shapes we use in our work, like the vascular networks of the liver and other organs.”

He said commercial SLS machines cannot usually fabricate objects with custom powdered materials, which is particularly important for researchers experimenting with biomaterials.

The team has already showed OpenSLS can be used to print a series of intricate objects from both nylon powder (commonly used for high-resolution 3-D sintering) and polycaprolactone, or PCL; a nontoxic polymer used to make templates for engineered bone.

“Our goal from the outset has been to do this in a way that makes it easy for other people to reproduce our work and help the field standardise on equipment and best practices,” said study co-author Ian Kinstlinger, a graduate student.

“We've open-sourced all the hardware designs and software modifications and shared them via Github.”

The Github files are accessible here.

More details are available in the full report, published in PLOS ONE.

The device is demonstrated in the video below.

Print

Print