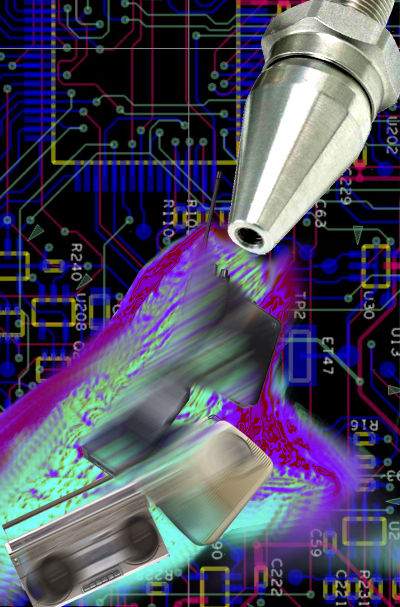

Nano-printing for new circuits

Australian engineers are working on a way to manipulate liquid metal to build circuits just a few atoms thick.

Australian engineers are working on a way to manipulate liquid metal to build circuits just a few atoms thick.

In what could be a big advance for tiny electronics, RMIT researchers are developing a process for the production of large wafers around 1.5 nanometres in depth (a sheet of paper, by comparison, is 100,000 nanometres thick).

The technique pinches some ideas from the rapidly-advancing world of 3D-printing.

RMIT’s Professor Kourosh Kalantar-zadeh led the project, which also included colleagues from RMIT and researchers from CSIRO, Monash University, North Carolina State University and the University of California.

He says the electronics industry is facing a major barrier.

“The fundamental technology of car engines has not progressed since 1920 and now the same is happening to electronics. Mobile phones and computers are no more powerful than five years ago,” Dr Kalantar-zadeh said.

“That is why this new 2D printing technique is so important – creating many layers of incredibly thin electronic chips on the same surface dramatically increases processing power and reduces costs.

“It will allow for the next revolution in electronics.”

Building electronic wafers just a few atoms thick could overcome the limitations of current chip production, according to Benjamin Carey, a researcher with RMIT and the CSIRO.

It could produce materials that are extremely bendable, and made to fit just about any shape or surface imaginable.

“However, none of the current technologies are able to create homogenous surfaces of atomically thin semiconductors on large surface areas that are useful for the industrial scale fabrication of chips,” he said.

“Our solution is to use the metals gallium and indium, which have a low melting point.

“These metals produce an atomically thin layer of oxide on their surface that naturally protects them. It is this thin oxide which we use in our fabrication method.

“By rolling the liquid metal, the oxide layer can be transferred on to an electronic wafer, which is then sulphurised. The surface of the wafer can be pre-treated to form individual transistors.

“We have used this novel method to create transistors and photo-detectors of very high gain and very high fabrication reliability in large scale.”

The paper outlining the new technique, “Wafer Scale Two Dimensional Semiconductors from Printed Oxide Skin of Liquid Metals”, has been published in the journal Nature Communications.

Print

Print