Lenses laid on the tip of a needle

German researchers can 3D-print miniscule lenses onto the tip of a needle.

German researchers can 3D-print miniscule lenses onto the tip of a needle.

The tiny lenses could pave the way for next-generation sensors, endoscopes (body cameras) and miniaturised robots.

The high-performance lenses can be printed directly onto tiny structures - such as the tip of optical fibres thinner than a needle – as they are only a fraction of a millimetre in size.

Multi-lens optical elements with non-spherical shapes are needed for high-end performance and to correct for aberrations.

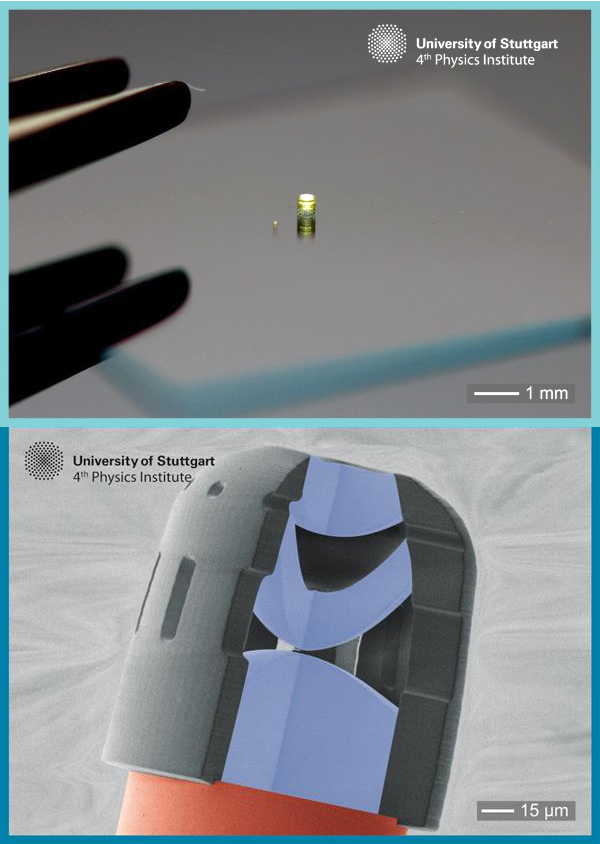

Research engineer Timo Gissibl and colleagues at the University of Stuttgart used a femtosecond laser writing system to 3D print multi-lens systems about 0.1 mm in size.

The multi-lens systems feature multiple singlet (simple) lenses that are combined into a compound lens within a supporting shell, all printed at a rate of centimetres per second.

In their latest experiments, the team printed a triplet lens system directly onto the end of an optical fibre that can fit inside a typical syringe needle.

They tested the final device, and showed that objects 3 mm from the lens could be successfully imaged at the other end of the 1.7-m-long optic fibre.

They also built an array of lens systems with four refractive interfaces can be printed onto 5-megapixel CMOS image sensors (used in digital cameras).

“Endoscopic applications will allow for non-invasive and non-destructive examination of small objects in the medical as well as the industrial sector,” the team wrote.

Dr Gissibl added; “The unprecedented flexibility of our method paves the way towards printed optical miniature instruments such as endoscopes, fibre-imaging systems for cell biology, new illumination systems, miniature optical fibre traps, integrated quantum emitters and detectors, and miniature drones and robots with autonomous vision.”

Print

Print