High-tech threads tested

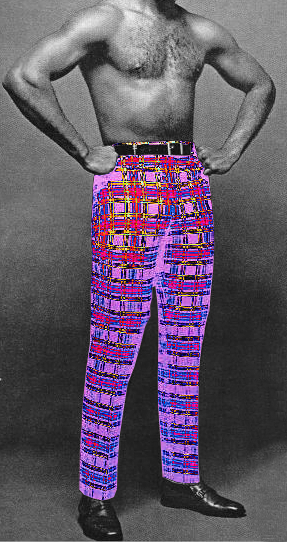

New fibres could form the fabric of programmable clothes.

New fibres could form the fabric of programmable clothes.

Researchers have unveiled a novel method for creating fibres with embedded electronics, creating conduits for electronic inputs and paving the way for programmable clothing.

Experts envision next-gen outfits that could monitor heart rates or other bio-signs, or create visual feedback to guide wearers through city streets.

Many are working on the smart clothing revolution, but the process of embedding electronics into fibres traditionally introduces defects, compromising their performance.

Addressing this issue, a team led by the Chinese Academy of Sciences has meticulously analysed the fibre manufacturing process, identifying the stages where fractures and defects are most likely to occur.

By tweaking the processing techniques and judiciously selecting the combination of semiconductors and fibre materials, they have engineered high-performance, flexible fibres with enhanced optoelectronic properties.

To showcase the practical applications of their work, the researchers knitted these fibres into a prototype hat that senses and reacts to traffic light signals.

This hat communicates with a smartphone, alerting the user to changes from red to green, a feature that promises to add a layer of safety for visually impaired individuals.

Similarly, they have woven the fibres into a wristband, creating a wearable heart monitor that rivals commercial devices in performance but exceeds them in comfort and fit.

The durability of these fibres under compression and their waterproof nature further extend their potential applications, including underwater uses.

What sets this technology apart, according to researchers Xiaoting Jia and Alex Parrott i, is its readiness for industrial production.

“The instrument that fabricates the fibres includes a fibre-drawing device that is used to produce commercial optical fibres in the telecommunication industry. And once the fibres are generated, they can be knitted or woven into fabric using tools that are already used widely in the textile industry,” they write.

By combining insights from mechanics, fluid dynamics, and semiconductor engineering, the team has laid the groundwork for a future where garments could play an active role in human health, safety, and daily interactions with technology.

Print

Print