Gas trap tested

A new material with a molecular trapdoor has been created for selective gas adsorption.

A new material with a molecular trapdoor has been created for selective gas adsorption.

An international research team led by scientists at City University of Hong Kong has discovered a new material that could revolutionise industrial gas separation.

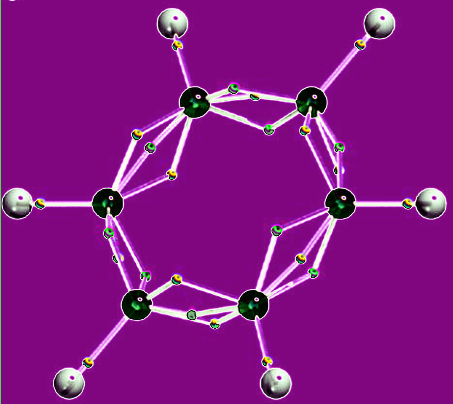

This material, a flexible metal-organic framework (MOF) with one-dimensional channels, acts as a “molecular trapdoor” to selectively adsorb gases such as carbon dioxide in response to temperature and pressure changes.

A recent study in the journal Small details a solid one-dimensional framework with internal voids capable of holding gas molecules.

Tests at the Australian Synchrotron showed the MOF's temperature-sensitive gas adsorption behaviour resembling the “molecular trapdoor” effect discovered a decade ago in CHA zeolite - a mineral with a three-dimensional framework structure.

The molecular trapdoor effect involves extra-framework anions - negatively charged ions not part of the main structural framework - that act as gates.

These gates shift positions under the influence of heat or pressure, allowing gas molecules to enter the framework.

This mechanism allows high gas selectivity, especially when gases have similar sizes and properties.

“Gas separation is crucial in numerous industrial contexts, including applications like natural gas separation, carbon capture, and hydrogen purification,” says Dr Qinfen Gu, Principal Beamline Scientist at the Australian Synchrotron.

However, achieving high selectivity for similar gases remains a challenging task.

The research demonstrated that different guest molecules create varying energy barriers for the movement of anions, enabling separation based on specific threshold temperatures.

The use of larger, spherical anions was found to improve selectivity for gases such as CO2/CH4 (Carbon dioxide and methane. Important for removing CO2 from natural gas), C3H6/C3H8 (Propylene and propane. Crucial in the petrochemical industry for producing polymers), and N2/CH4 (Nitrogen and methane. Needed to purify natural gas by removing nitrogen).

Although this behaviour was observed at low temperatures with limited separation capabilities, the findings suggest potential for designing other types of MOFs with enhanced performance.

“This finding challenges the traditional view that gas adsorption is only about gas affinity or size-based sieving,” said Professor Jin Shang, Associate Professor at the School of Energy and Environment, City University of Hong Kong.

“It highlights the role of guest-induced anion movements in gas diffusion within MOFs.”

The research team conducted comprehensive investigations into the flexibility of MOFs with respect to temperature.

Typically, temperature-triggered gate-opening behaviour in MOFs is associated with structural transformations.

To explore this, the team performed in situ single-crystal X-ray diffraction and synchrotron powder X-ray diffraction experiments at various temperatures, using the macromolecular crystallography and powder diffraction beamlines at the Australian Synchrotron.

“XRD diffraction was used to understand the flexibility of the structural framework and the movement of anions as gate-keepers in response to temperature,” said Dr Gu.

“It also confirmed the success of anion exchange and determined the exchange rate.”

Dr Stefanie Bird, a Macromolecular Crystallography Beamline Scientist, assisted with single-crystal measurements, which provided detailed information about structural changes at different temperatures.

The researchers believe that this discovery could pave the way for creating “molecular trapdoor” MOFs with higher surface areas, offering better capacity and separation performance.

Such advancements could significantly impact various industrial processes, enhancing efficiency and sustainability in gas separation applications.

Print

Print