Better metal through simple strains at Monash

A new technique is being developed in Australian labs, which promises to produce metals with greater strength, better corrosion resistance and increased biocompatibility.

A new technique is being developed in Australian labs, which promises to produce metals with greater strength, better corrosion resistance and increased biocompatibility.

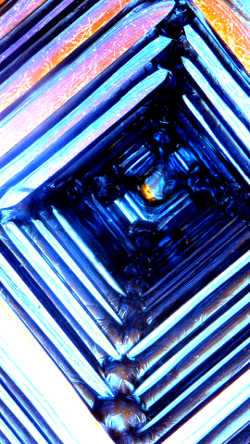

The technique is a surprisingly simple concept: metal is forced through custom-made moulds or dies, fundamentally changing its structure.

The new nanostructuring technique is the result of research by Professor Yuri Estrin at Monash University’s Centre for Advanced Hybrid Materials.

“Metals are actually made of small crystallites, or grains,” Professor Estrin says.

“Applying mechanical load to deform the metal in specially designed processes breaks these into smaller and smaller fragments, down to a nanoscale granularity, while maintaining the material’s overall structure.”

The more times the metal is pushed through the die, the smaller the grains become; the smaller the grains, the stronger the material, although there is a natural limit to both the reduction in grain size and the improved strength.

Using this technique, or variations of it, often repeated many times, Professor Estrin and his principal co-researcher, Associate Professor Rimma Lapovok, have increased the strength of titanium by up to 30 per cent.

An even more spectacular increase – by a factor of eight – was achieved with pure copper.

The team behind the project is focused on the potential of enhanced titanium for dental implants.

The titanium alloy currently used for this purpose includes aluminium and vanadium to provide additional strength, but both elements are considered by some to be potentially toxic.

“Dental surgeons would like to have pure titanium. It is more biocompatible, but it doesn’t have the strength of the alloy. However, we can take commercially pure titanium and use nanostructuring to give the material extra strength. This leaner, cleaner and stronger titanium compensates for the loss of the alloying elements,” Professor Estrin said.

The nanostructuring techniques are comparatively simple, but Professor Estrin said he continues to discover possible ways of making materials more functional for a variety of purposes.

Lighter, stronger metals are sought after in the automotive and aviation industries as well as in biomedicine.

More information is available in a report produced by Monash University.

Print

Print