3D-printers give a cheap hand to prosthetics

A group of Queensland robotics students are working on a way to smash the cost of prosthetic limbs - by 3D-printing them.

A group of Queensland robotics students are working on a way to smash the cost of prosthetic limbs - by 3D-printing them.

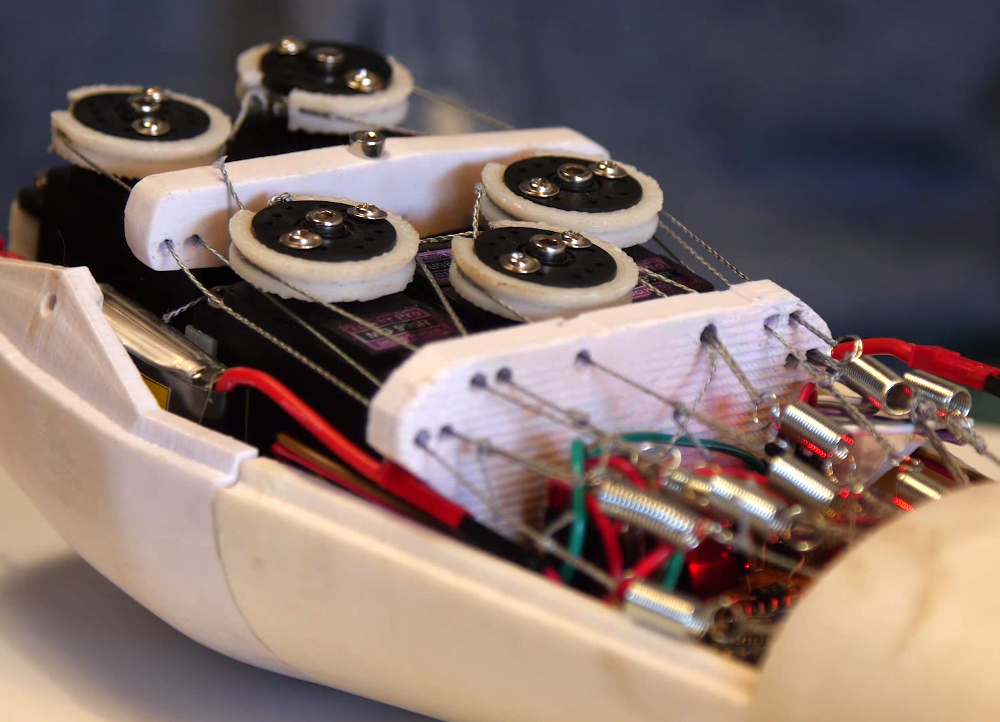

UQ Robotics Club students are spending this semester creating a functioning prosthetic forearm to advance open-source knowledge for the creation of 3D printed prosthetics.

Project manager Lex Van Cooten says the team has spent six months working on prototypes before coming to its current model.

“We used files from an open-source humanoid robot arm, and now we’re working on how to get it to interface with the human body,” he said.

“It uses EMG (electromyography) – a very basic signal process that responds to connections on the muscles, that essentially opens and closes the hand.

“The next step is being able to grip things, which is where most commercial units are at.”

The club is working with amputees to test the unit.

“The only thing we have available to us at the moment is cosmetic prosthetic arms,” amputee Ben Tarbuck said.

“They kind of just hang there like a dead weight and are good for nothing, or you can get a freaky-looking hook,” he said.

“Having an arm that’s functional, and also accessible financially for people, would be a good move in the right direction.”

Mr Van Cooten said the students would use what they learned to contribute to other open-source files on building prosthetics.

“It’s a very active area,” he said.

“There are a lot of financial challenges for people seeking prosthetics. They can cost $10,000 per component and there’s no room for customisation.

“We wanted to build something useful, to have fun but also add value. If we can bring something back to the open-source community and bring forward affordable limbs, that would be the ultimate goal.”

So far, the 3D printed limb costs around $500 to make.

The project has been funded through a UQ Sponsorship Grant, with robotics club member Fabian Vasuain acting as head engineer.

The club is seeking help on the project, and says anyone interested can contact them through their official site.

Print

Print