Windmills just millimetres across could charge the future

Research engineers in the US have designed a micro-windmill that yield a tiny new level of energy gathering.

Research engineers in the US have designed a micro-windmill that yield a tiny new level of energy gathering.

The micro-windmills could be applied to mobile phone cases, the outside of cars and buildings, and virtually any other surface with a light breeze. The design comes from a small team at the University of Texas.

Designers say about ten of the miniscule mills could be packed onto a single grain of rice, with spinning blades measuring just 1.8mm across.

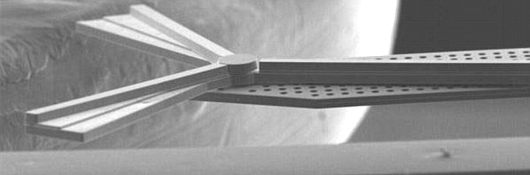

The schematic for the micro-windmill blends an origami-like layout with conventional wafer-scale semiconductor devices, which can be assembled into complex 3-D mechanical structures from two-dimensional metal pieces.

The design was prompted by a push for new devices by a Taiwanese company specialising in the microscopic wafer manufacturing technique.

The same engineers have completed designs for gears, inductors, pop-up switches and grippers, all measuring a fraction of the width of a human hair and to be produced by the same Taiwanese company.

The micro-windmills are made from a nickel alloy prized for its ease of use at such small scales.

“The micro-windmills work well because the metal alloy is flexible and [the] design follows minimalism for functionality.” University of Texas engineer J.C. Chiao said.

The miniature energy harvesters can be made in batches of thousands on a single wafer, with fabrication costs virtually the same for one or multitudinous copies.

“Imagine that they can be cheaply made on the surfaces of portable electronics,” Chiao says

“So you can place them on a sleeve for your smart phone. When the phone is out of battery power, all you need to do is to put on the sleeve, wave the phone in the air for a few minutes and you can use the phone again.”

In an agreement reached with the manufacturers, the engineers have been allowed to retain the intellectual property rights to their creations.

Print

Print