Graphene graft gives new drug checking base

Sensing chemicals is one of the fundamental tasks in almost every biological process, but engineers have now taken this natural ability and re-purposed it for technological use.

Sensing chemicals is one of the fundamental tasks in almost every biological process, but engineers have now taken this natural ability and re-purposed it for technological use.

Using the particular sensing abilities of one receptor, researchers have developed a device which could be used for extremely rapid drug development and diagnosis.

The human body’s many different receptors are shaped to accept certain target chemicals. When they bind, the receptors tell their host cells to produce nerve impulses, regulate metabolism, defend the body against invaders or myriad other actions depending on the cell, receptor and chemical type.

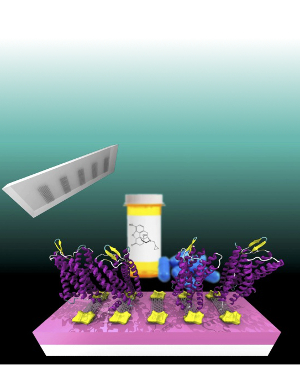

A team from the US attached a modified version of the mu-opioid receptor to strips of graphene. The mu-opioid receptor is critical in the action of painkillers and anaesthetics.

The study has shown a way to mass produce devices that could be useful in a variety of diagnostic tests and drug development. Because the mu-opioid receptor belongs to the most common class of such chemical sensors, the findings suggest that the same technique could be applied to detect a wide range of biologically relevant chemicals.

The project brought together experts from a range of fields, including physics, anaesthesiology, chemistry and engineering.

The project yielded a computationally redesigned protein which could be readily grown and attached directly to graphene, opening up the possibility of mass producing biosensor devices that utilise these receptors.

“Due to the challenges associated with isolating these receptors from their membrane environment without losing functionality, the traditional methods of studying them involved indirectly investigating the interactions between opioid and the receptor via radioactive or fluorescent labelled ligands, for example,” said Renyu Liu a professor of anaesthesiology.

“This multi-disciplinary effort overcame those difficulties, enabling us to investigate these interactions directly in a cell free system without the need to label any ligands.”

A.T. Charlie Johnson, director of Pennsylvania State University’s Nano/Bio Interface Center, describes the novel process.

“We start by growing a piece of graphene that is about six inches wide by 12 inches long,” Johnson said.

“That’s a pretty big piece of graphene, but we don't work with the whole thing at once... [We] came up with a very clever idea to cut down on chemical contamination. We start with a piece that is about an inch square, then separate them into ribbons that are about 50 microns across.

“The nice thing about these ribbons is that we can put them right on top of the rest of the circuitry, and then go on to attach the receptors. This really reduces the potential for contamination, which is important because contamination greatly degrades the electrical properties we measure.”

Because the mechanism by which the device reports on the presence of the target molecule relies only on the receptor’s proximity to the nanostructure when it binds to the target, Johnson’s team could employ the same chemical technique for attaching the antibodies and other receptors used in earlier studies.

Once attached to the ribbons, the opioid receptors would produce changes in the surrounding graphene’s electrical properties whenever they bound to their target. Those changes would then produce electrical signals that would be transmitted to a computer via neighbouring electrodes.

The high reliability of the manufacturing process — only one of the 193 devices on the chip failed — enables applications in both clinical diagnostics and further research.

“We can measure each device individually and average the results, which greatly reduces the noise,” said Johnson. “Or you could imagine attaching 10 different kinds of receptors to 20 devices each, all on the same chip, if you wanted to test for multiple chemicals at once.”

Print

Print