CO2 turned useful

Engineers are converting carbon dioxide emissions into chemical building blocks for fuel and plastics.

Engineers are converting carbon dioxide emissions into chemical building blocks for fuel and plastics.

Researchers at UNSW’s School of Chemical Engineering have created nanoparticles that act as the catalyst for turning carbon dioxide into ‘syngas’ – a mix of hydrogen and carbon monoxide used in the manufacture of industrial products.

The new method is cheaper and more scalable to the requirements of heavy industry than what is available today.

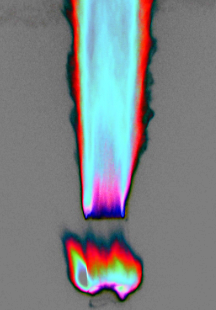

“We used an open flame, which burns at 2000 degrees, to create nanoparticles of zinc oxide that can then be used to convert CO2, using electricity, into syngas,” says Dr Emma Lovell.

“Syngas is often considered the chemical equivalent of Lego because the two building blocks – hydrogen and carbon monoxide – can be used in different ratios to make things like synthetic diesel, methanol, alcohol or plastics, which are very important industrial precursors.

“So essentially what we’re doing is converting CO2 into these precursors that can be used to make all these vital industrial chemicals.

The researchers say in effect, they are closing the carbon loop in industrial processes that create harmful greenhouse gases, and by making small adjustments to the way the nanoparticles are burned by the FSP technique, they can determine the eventual mix of the syngas building blocks produced by the carbon dioxide conversion.

“At the moment you generate syngas by using natural gas – so from fossil fuels,” Dr Rahman Daiyan says.

“But we’re using waste carbon dioxide and then converting it to syngas in a ratio depending on which industry you want to use it in.”

For example, a one to one ratio between the carbon monoxide and hydrogen lends itself to syngas that can be used as fuel, but a ratio of four parts carbon monoxide and one part hydrogen is suitable for the creation of plastics, Dr Daiyan says.

The team says the technique can be scaled up.

“The idea is that we can take a point source of CO2, such as a coal fired power plant, a gas power plant, or even a natural gas mine where you liberate a huge amount of pure CO2 and we can essentially retrofit this technology at the back end of these plants. Then you could capture that produced CO2 and convert it into something that is hugely valuable to industry,” says Dr Lovell.

The group’s next project will be to test their nanomaterials in a flue gas setting to ensure they are tolerant to the harsh conditions and other chemicals found in industrial waste gas.

Print

Print