Big step forward in multi-material 3D printer

Engineers have unveiled an exciting advance in the field of 3D-printing, with a device that can print in 10 different materials.

Engineers have unveiled an exciting advance in the field of 3D-printing, with a device that can print in 10 different materials.

MIT researchers say the device could be used to print whole, completed objects – not just parts and prototypes.

It opens the possibility of being able to produce entire circuit boards, electronic devices or even robots from a single machine.

Currently, most 3D printers print in just one material, mostly plastic, metal, ceramics and wood. While multi-material printers exist, they are often capable of handling only two substances, and have until now been exorbitantly expensive.

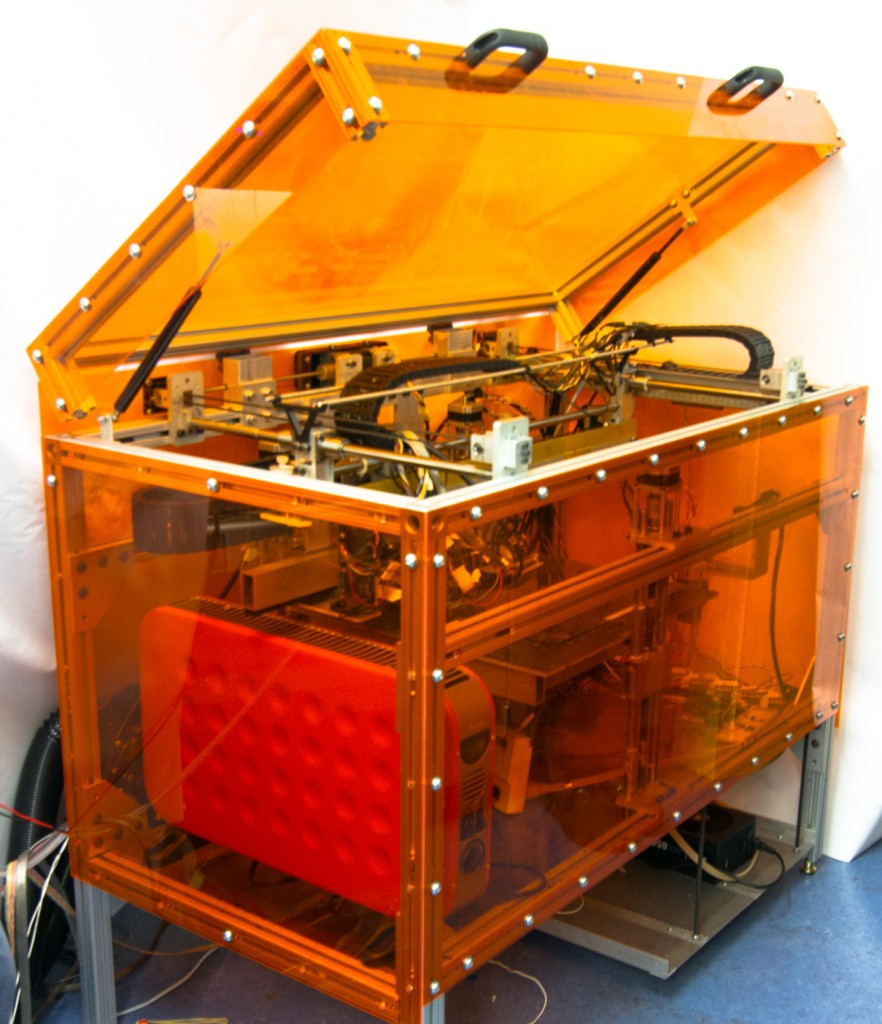

But a team from MIT's Computer Science and Artificial Intelligence Laboratory (CSAIL) say their new MultiFab 3D printer is an all-in-one system that should cost just $7,000.

That is an extremely low cost for something that can quickly print out multi-material, multi-component objects with very little hassle.

The device is described in detail in the open access paper; “MultiFab: A Machine Vision Assisted Platform for Multi-material 3D Printing” (PDF).

Aside from its ability to work in multiple materials, the MultiFab unit uses ‘machine vision’ to understand and enhance its products.

Using a system of 3D scanners, MultiFab can self-calibrate and self-correct any mistakes. It constantly monitors and adjusts the printing process, deciding which materials need to be printed onto the object and in what order.

But it cannot do it all itself, and so allows the user to take specialised components and insert them into the machine. It then prints on and around the special parts to incorporate them into the final product.

“With MultiFab, we integrate these two worlds of traditional manufacturing with 3D printing, and by putting them together, we can make a whole range of new objects that we are not currently able to make today,” said Javier Ramos, a research engineer with CSAIL and co-author of the research paper.

“Right now, 3D printers are focused on printing form and objects for prototype, but the Holy Grail would be to print out things that are fully functional right out of the printer, combining multiple materials with many properties.”

The researchers have demonstrated the machine by printing out LED lenses, a plastic blade holder containing a metal blade in it, and smartphone cases that were printed around the phone itself.

They say this is just the start, as they see MultiFab applied in the production of consumer electronics, medical imaging, microsensing and telecommunications.

They are now working to print objects with embedded motors and actuators, chasing the possibility of being able to 3D print advanced electronics and entire machines.

“Designers and engineers are used to designing with just one material, so the whole design paradigm will have to change. That's going to require new hardware and software, and we're going to have to change the way us engineers and designers think about design,” said Ramos.

“Picture someone who sells electric wine-openers, but doesn't have $7,000 to buy a printer like this. In the future they could walk into a FedEx with a design and print out batches of their finished product at a reasonable price. For me, a practical use like that would be the ultimate dream.”

Print

Print